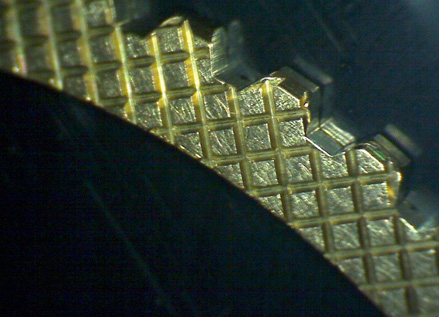

Serra Manufacturing Corporation specializes in aerospace oriented CNC machining designed to meet the standards and tolerances of this demanding industry. This .088″ thick nickel aluminum bronze alloy splined washer has an outer diameter of approximately 3.42″ and is machined to dimensional tolerances as tight as ±.0005″. The initial washer shape was turned on our CNC lathe. External splines were broached, the serration pattern was cut in our CNC mill, and the washer was processed through our double disk grinder. Double disk grinding is an ideal solution for this type of flat component. We are able to achieve superior dimensional tolerances, flatness, and parallelism while processing parts twice as fast as traditional grinding methods.

Washers were inspected using visual, dimensional, and penetrant inspection techniques to ensure all customer specifications were met. Our quality systems are certified under both ISO 9001:2008 and AS9100C. We produce over 10,000 of these specialty washers annually and offer JIT delivery services to our customer in the aerospace industry. For more information about this aerospace CNC machining project, see the table below, or contact us directly.

CNC Machining Of A Nickel Aluminum Bronze Splined Washer Specifications:

- Capabilities Applied/Processes

- Primary:

CNC Turning

Broaching – External Spline

Double Disc Grinding

CNC Milling – Serrations - Secondary:

De-Burring

- Primary:

- Overall Part Dimensions

- Outside Diameter: Ø 3.416 / 3.421″

Inside Diameter: Ø 2.995 / 3.005″

- Tightest Tolerances

- ± 0.0005″

- Material Used

- Nickel Aluminum Bronze

Thickness: 0.088″

- Material Finish

- Machined Finish

- In Process Testing/Inspection Performed

- Dimensional Inspection, Visual Inspection, Penetrant Inspection

- Industry For Use

- Aerospace

- Volume

- 10,000+

- Delivery/Turnaround Time

- Made To Delivery Forecast

- Delivery Location

- California

- Standards Met

- Customer Specifications, 2D CAD Drawing

ISO9001:2008

AS9100 Rev C

- Product Name

- Serration Splined Washer