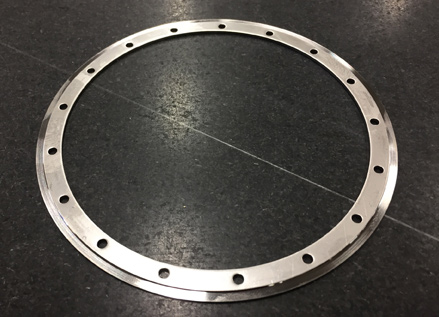

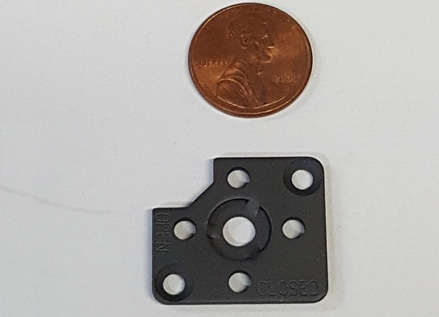

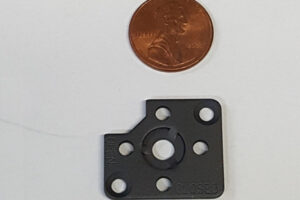

Serra Manufacturing Corporation is a leading provider of precision stamping services to the aerospace, military, medical, and other commercial industries. Our extensive stamping capabilities include single stamping, progressive dies, forming, blanking, and deep drawing. Our mechanical and hydraulic presses range from 12 to 176 tons with a maximum press speed of 200 cycles/min and feed rate of 10 in/sec to 99 in/sec. This versatile equipment allows us to create a variety of components including washers, gaskets, cups and clips. We manufacture metal parts from a wide range of materials including steel alloys, nickel, titanium and bronze. Metal parts can be manufactured in diameters between .075″ and 20″. We can also stamp parts from nonmetallic materials including synthetic rubber, nylon and teflon with diameters between .125″ and 15″. Parts can range in thickness from .005″ to .25″ with draw depths up to 4″.

Our parts are widely used throughout the aerospace industry with many of our customers sending parts directly to stock without any additional inspection. We specialize in precision work with tolerances as tight as ±.0002″. All tooling is built in-house, giving us complete control over quality. Additional services include deburring, double disk grinding, lapping, serration, packaging and EDI capable shipping. We are very active in continuous improvement programs including SPC, Six Sigma, Kaizen and other lean manufacturing methodologies. We believe this dedication to improvement and training shows through our long term relationships with our customers and reputation for trusted quality in some of the most demanding manufacturing industries. For more information about our precision stamping services, see the table below, or contact us directly.

Precision Stamping Capabilities:

- Stamping Production Method

- Hydraulic Punch Press

Mechanical Punch Press

Single Stamping

Progressive Die

Forming - Blanking

Deep Draw

Compound

Laminating

- Hydraulic Punch Press

- Machining Services

- Countersinking

Reaming

Milling - Turning

Double Disc Grinding

Lapping

- Countersinking

- Press Rating

- 12 To 176 Tons

- Press Speed

- 200 Cycles/Min

- Maximum Feed Rate

- 99 in/sec

- Maximum Press Stroke

- 12 in

- Maximum Press Bed Length

- 36 in

- Maximum Press Bed Width

- 36 in

- Metal Part Diameter

- .075 to 20 in

- Non-Metal Part Diameter

- .125 to 15 in

- Part Thickness

- .005 to .25 in

- Draw

- Up to 4 in

- Tolerance (+/-)

- .0002 in

- Metal Materials

- Stainless Steel

Aluminum

Titanium

Hastelloy

Waspalloy - Nickel

Steel

Copper

Bronze

Brass

- Stainless Steel

- Non-Metal Materials

- Synthetic Rubbers

Teflon

Nylon

- Stamping Products

- Shims

Washers

Gaskets

Brackets - Rings

Cups

Clips

- Shims

- Additional Services Provided

- In House Tooling

Deburring

Packaging

Shipping (EDI Capable) - Lapping

Double Disk Grinding

Serration

- In House Tooling

- Production Volume

- Small to Large Runs (Depending On Complexity Of Parts)

- Typical Lead Time

- 2 to 8 Weeks

Rush Services Available

Additional Information

- Industry Focus

- Aircraft

Aerospace

Commercial - Military

Medical

- Aircraft

- Industry Standards

- ISO 9001:2008

5S

FCC

AS

AMS

ASTM - Mil Specs

DOE

Lean Manufacturing

Six Sigma

US Small Business Administration Award for Excellence

- ISO 9001:2008

- Efficiency

- Lean Manufacturing

Kaizen

SPC - Six Sigma

Design of Experiments

- Lean Manufacturing

- File Formats

- AutoCAD

MasterCAM - PDF

Images

- AutoCAD